You’ve got yourself a new set of fork springs to throw in your dirt bike but you’re not real sure on where to start when it comes to fitting them. Here’s how – with twin-chamber forks.

Fitting Fork Springs

Step 1. Clean

Remove the fork legs from the bike and give them a nice clean so there is no dirt that can fall inside, then prepare a nice clean work space. The last thing you want is any dirt getting inside your fork legs and causing damage.

Step 2. Loosen the bottom nut

Turn the fork legs upside down and undo the bottom nut using either a rattle gun or by holding the fork leg in a vice and loosening the nut with a socket and rachet.

Step 3. Push down

Once the nut is loose you can place the fork leg upside down and push down on it until the internal rod comes out through the bottom of the fork leg. You will need to use the correct damper rod holding tool or an open-ended spanner to stop the damper rod from retracting back inside the fork leg. Loosen the lock nut and remove the bottom cap from the damper rod.

Step 4. Pull it apart

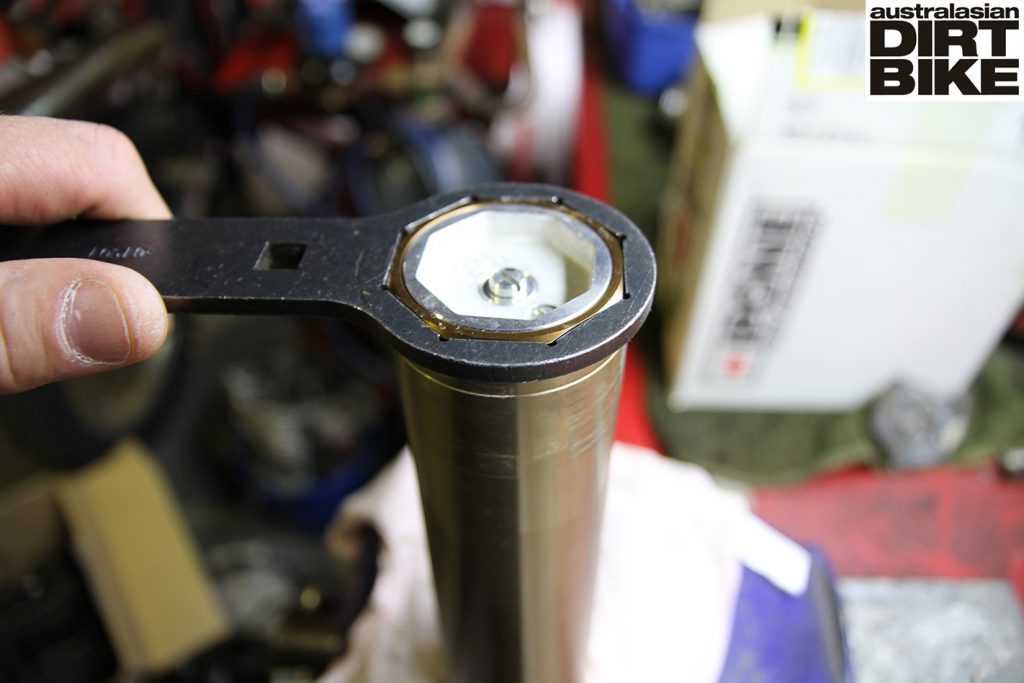

Drain out the oil and then place the fork in the vice and, using the correct shock tool or a very large shifting spanner, undo the top fork cap and slide out the inner cartridge. Once you have taken out the inner cartridge you can pull out the fork spring and replace it.

Step 5. Wind it up

Slide the inner cartridge and new fork spring back together, compress the fork leg again so you can hold the damping rod though the bottom of the fork leg and retighten the lock nut and cap. The correct method is to wind the lock nut all the way back on the damper rod and wind your clicker adjustments all the way out (anti clockwise). Wind the bottom cap all the way onto the damper rod until it stops then tighten the lock nut back against the cap. Then re-set your clicker adjusters and tighten the bottom fork cap.

Step 6. Fill, fit and ride

Re-fill the forklegs with the correct amount of oil and re-fit them back into the bike and go riding.

TIPS

• Make sure the correct amount of oil is used when refilling the fork legs after fitting the springs. If the incorrect amount or the oil weight is wrong, the suspension action will be off.

• Before shelling out your hard earned on new springs, try having the suspension setup for tyour ability and weight.

• This method for changing springs is only relevant to typical closed cartridge forks. If you are planning on changing the spring rate in

your air fork or seperate function fork, take it to a professional.

DOs

• Clean the fork legs as much as possible and prepare a clean work area before starting

• Discard of the old oil properly, not down the drain or in the garbo

• When working, place the fork leg on a wood block or piece of carpet or rubber, not directly on the concrete

• Use the correct fork tools if possible to prevent damage to the fork

DON’Ts

• Never use vice grips or any type of pliers to hold the damper rod as you will scratch it and will cause the internal damper rod seal to leak

• There is no need to over-tighten the damper rod lock nut or either fork caps as they all have o-rings or copper washers which prevent the oil from leaking out.

• Be very careful not to mark any internal fork components as this could hinder the performance of your fork

Read more How-Tos HERE.